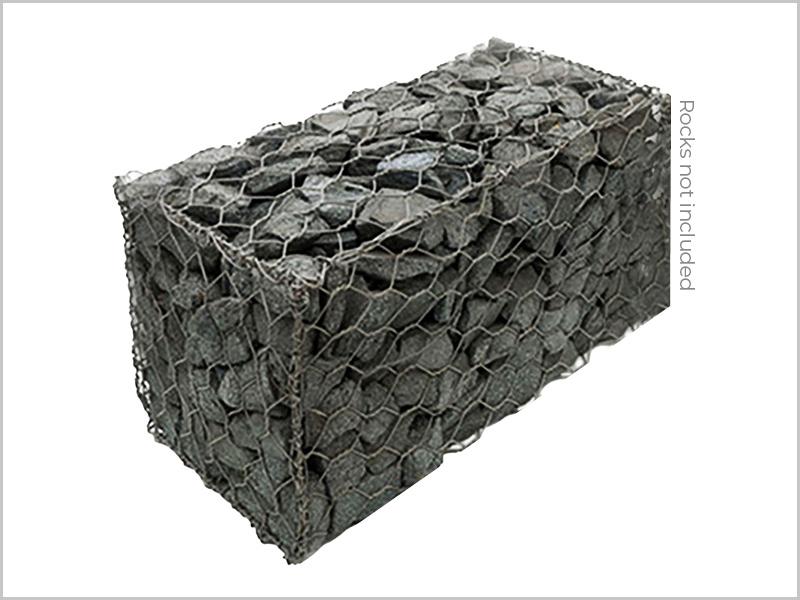

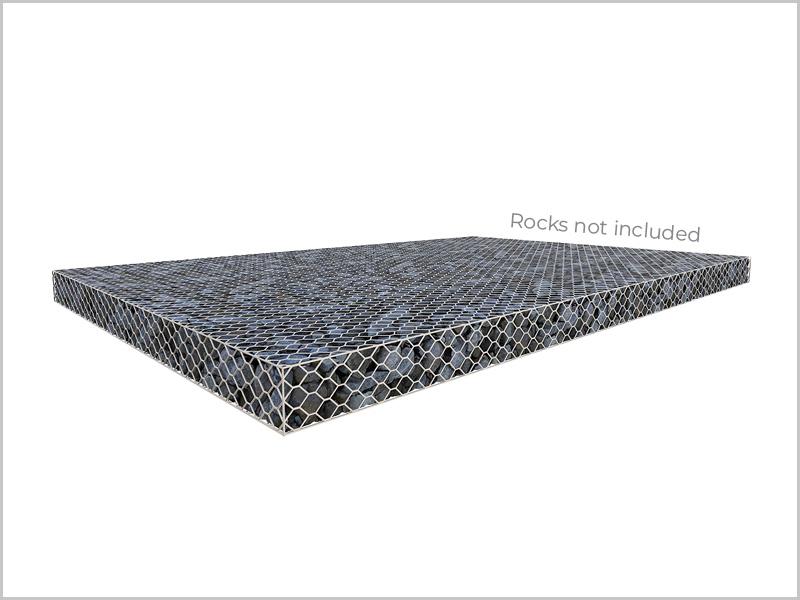

Maccaferri® Reno Mattresses, also known as rock mattresses, are thin, flexible rectangular mesh cages made from double twisted "DT" woven wire mesh. The cages are divided into cells and filled with rock to limit movement during high-flow conditions. Because of their flexibility, they are used mainly for hydraulic applications such as weirs, and for scour protection along riverbanks and embankment stability in channel linings. Mattresses can handle water velocities in excess of 6m/sec for long durations.

Our reno mattresses are made from double twist hexagonal wire mesh using PoliMac®, a polymer coating, and are supplied 6m x 2m dimensions with a thickness less than 500mm.

Reno mattresses are filled with stones on site to create a flexible, permeable and monolithic structure for use in river and canal bank protection works as well as erosion control and scour protection of slopes.

Hydraulic testing has shown that by containing rock within the cells of the mattresses the resistance to rock movement under high flows is dramatically reduced resulting in the use of smaller and less rock for channel lining works.

WHY CHOOSE MACCAFERRI RENO MATTRESSES?

- Improves stability on soil banks and protects soil from erosion and scouring

- Over 73% more effective than using rip-rap in applications with high values of shear stress

- Offers a permanent solution for hydraulic applications such as weirs, and for scour protection along riverbanks and embankment stability in channel linings

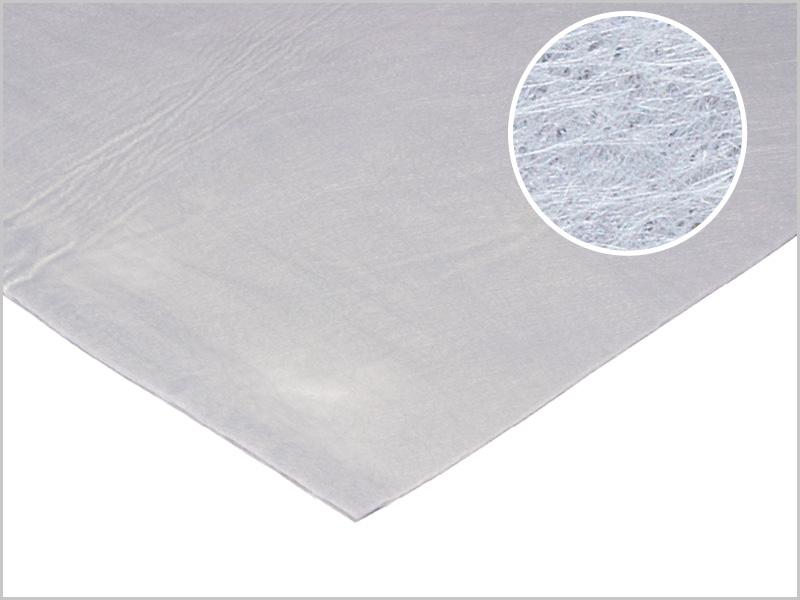

- Highly permeable which encourages the entrapment of sediment and seed along the water course, contributing to the health and diversity of the natural habitat

- Flexible and versatile to match existing soil profiles and can be shaped to zone a specific area for eco-system regeneration

- Made from one continuous mesh panel with no joints to weaken the structure

- Double diaphragm improves rockfill confinement, resulting in increased structural integrity

- PoliMac polymer coating provides 10x resistance to abrasion, 2x resistance to chemicals and 4x resistance to UV rays compared to traditional wire mesh products

- Independently verified and tested with BBA-HAPAS certification

- Design support including access to an advanced suite of software free to our clients and on-going in-house training or via seminars

- Supported with specialist installation tools for hire including pneumatic lacing tools lacing or you can purchase "C" rings and preformed bracing wires to reduce assembly time by up to 50%

Installation

Dense quarried stone is normally used to fill reno mattresses. To ensure the durability of the structure, the rock should be weather resistant, non-friable, insoluble and sufficiently hard. The most appropriate rock size falls in the range of 75mm to a maximum of two-thirds the thickness of the mattress, or 250mm, whichever is the lesser. Reno mattresses can be installed in place or can be crane placed into position. This makes them ideal for use in hydraulic applications for use both under and above water.