GABION BAFFLE SYSTEM

GHD Consulting Engineers were engaged to design and manage construction of upgrades to the Mount Barker Wastewater Treatment Plant (WWTP) for the District Council of Mount Barker, which is located about 35 km east of Adelaide. The WWTP receives effluent from septic tanks after which the treated effluent is reused in gardens and agriculture. A major aspect of this upgrade was to provide the redesign of an existing aeration lagoon.

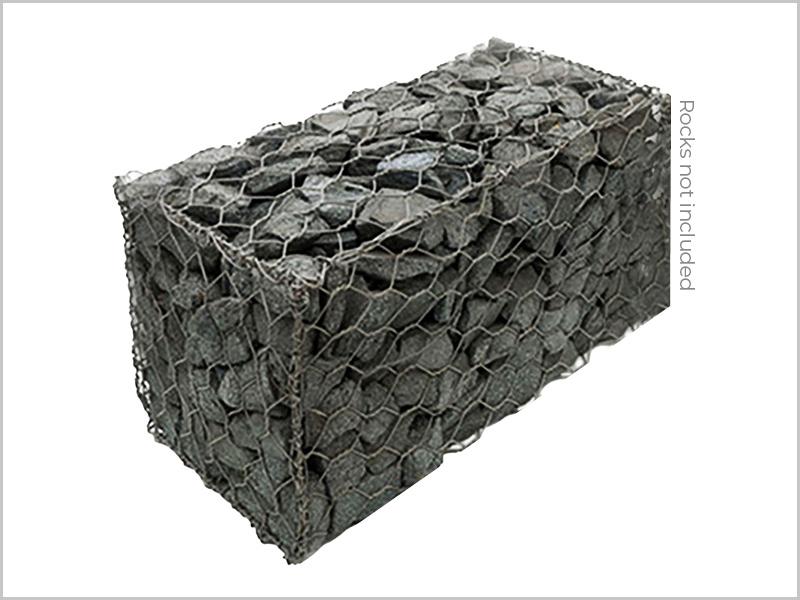

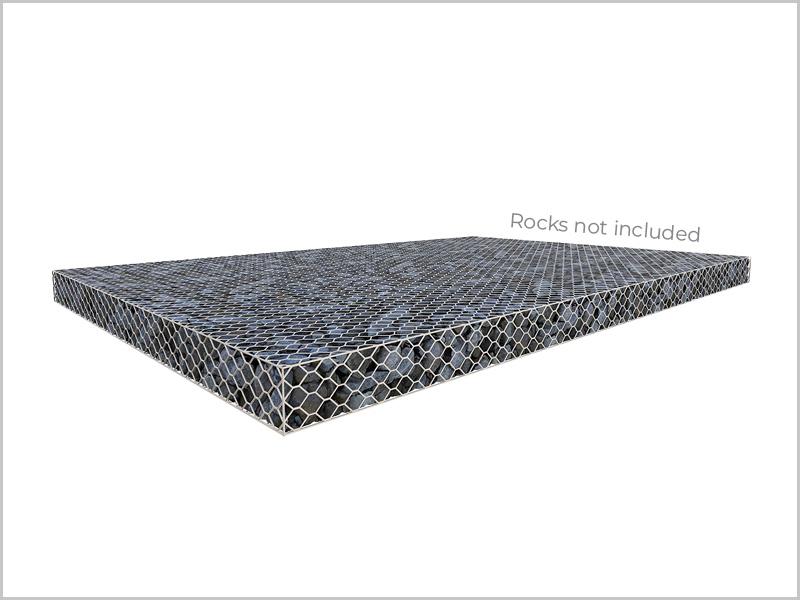

A suitable baffle system, which was challenging due to the size of the lagoon (200 m x 130 m x 3.5 m Deep), was achieved through the design and construction of four free standing Gabion walls, each approximately 90 m long by 3.5 m high.

The large wind and wave loadings resulting from the long length of baffles and the distance between them ruled out traditional baffle methods such as fabric curtains or fence construction. It was also necessary to maximise the wastewater volume in the lagoon, therefore construction of bulky earth embankments was not a viable option. The ideal solution would need to accommodate differential settlements due to poor foundation conditions, would need to be long lasting, quick to install, withstand wave and wind loads, be as vertical as possible and be cost effective. The walls were initially designed to include an impermeable clay membrane housed between gabion wall cages on either side. The motivation for this was to ensure the wastewater in the lagoon would not short circuit through the gabion walls, which are permeable.

However, upon further consideration and in order to optimise costs, this was considered unnecessary since there would be minimal flow through the gabions as compared to the flow in the lagoon around the gabion walls. It is also anticipated that the gabion walls will become less permeable over time as sludge settles between the voids.

The client was initially concerned that the gabions could be subject to excessive corrosion and not provide the required long term solution. This problem was resolved by utilising Maccaferri Galmac (95% Zinc 5% Aluminium alloy) + polymer coated gabions and reno mattresses. The Galmac coating is proven to provide up to three times the protection offered by a Zinc coating of the same mass. Comprehensive documentation and design assistance was provided by Maccaferri in this regard.

DOWNLOAD THE CASE STUDY