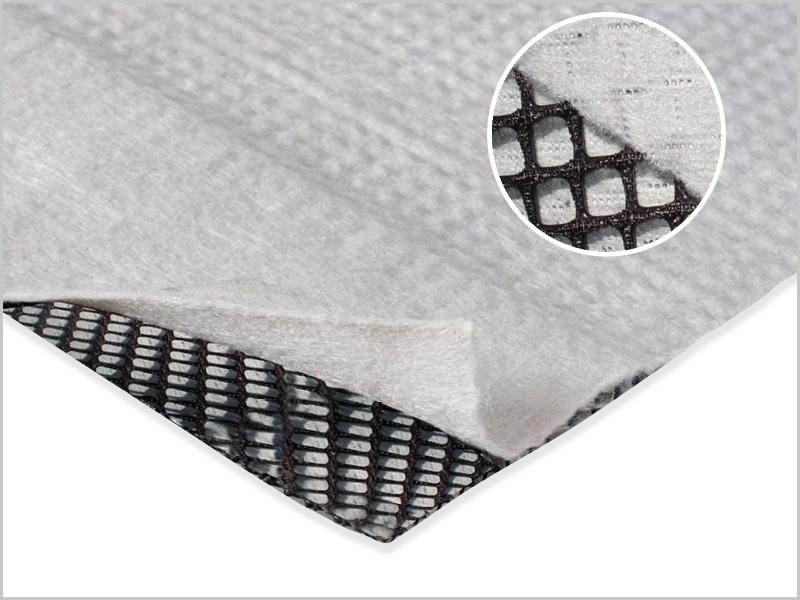

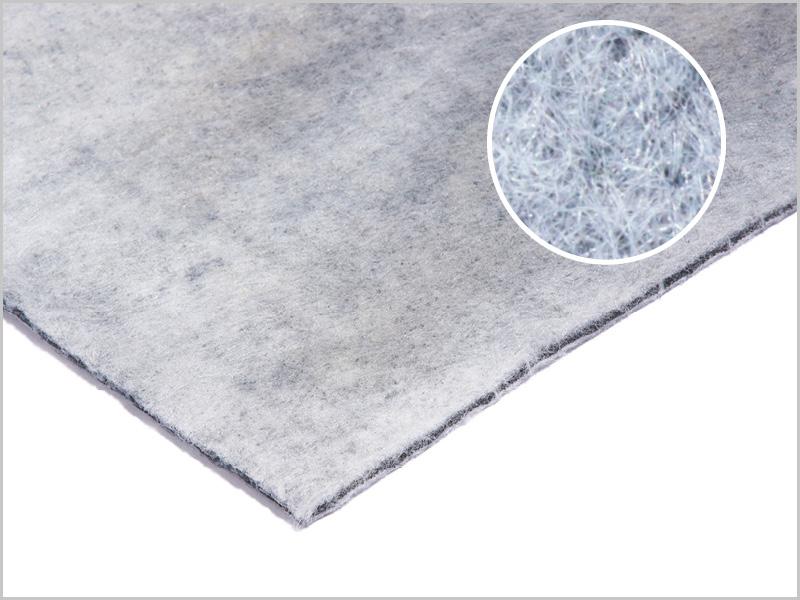

Trinet® triplanar drainage geocomposite is made from lightweight high-density polyethylene (HDPE) and designed with a thin three-dimensional composite construction.

It is an economical and effective water, gas and leachate drainage system for use in landfill bases & side slopes, landfill caps, tailings dams, tunnels, bridge abutments and retaining walls. Trinet triplanar drainage geocomposite offer engineers a proven alternative to traditional thick gravel drainage layers.

WHY CHOOSE TRINET DRAINAGE GEOCOMPOSITE?

- Economical alternative to traditional granular drainage layers due to better optimisation of landfill space and faster installation of lightweight composite

- Durable and crush-resistant with the capacity to withstand high loads exceeding 450kPa

- High through-flow capacity for rapid drainage while simultaneously preventing fine soil particles from migrating into the drainage core

- Protects the structure from damage caused by backfill material

- Simple installation process, reducing the time required to construct the drainage layer system

- Reduces safety risks on construction sites as the drainage nets are lightweight and simple to install, and minimises the damage to adjacent structures or materials, such as plastic liners

- Proven track record in landfill and mining projects throughout Australia and New Zealand

- Available in rolls up to 3.7m wide and a minimum length of 55m

- Available with single or double sided geotextile, with lighter or heavier grades depending on the specialist applications

The Geofabrics Geosynthetic Innovation, Research & Development (GRID) laboratory offers a service to modify the Trinet drainage geocomposites, depending on site specific requirements. Preliminary or complex designs can be proven prior to final design through the GRID to ensure economic and efficient geocomposites with optimised drainage capacities. Additionally, compatibility testing at the GRID ensures the site-specific liquor or leachate drains quickly within the drainage system.