Geosynthetics for Defence

Geosynthetic engineering on defence projects is the use of synthetic materials to achieve more cost-effective, environmentally sound and safer construction outcomes. The design techniques bring specific benefits to defence sites because geosynthetics maximise the use of site soils and avoid the need to import other construction materials. The fundamental benefits of using geosynthetics on defence sites are to:

- Save costs by replacing high volumes of soil material required to build civil engineering infrastructure, particularly in remote locations

- Remove the risk of variability in traditional engineering applications. By implementing geosynthetic solutions, variability in the design is not only de-risked, it also improves the long-term performance

- By reducing the volumes of soil material required, there is less need to quarry and fewer heavy machinery or transport required to build infrastructure which reduces the carbon footprint. Surface erosion systems also protect waterways from dust and sediment

- Reduce military personnel exposure to dangerous working conditions or protect what is important – military personnel, citizens or critical assets

APPLICATIONS

Ground & Pavement Stabilisation

Geofabrics geosynthetics and geotextiles are used in roads and heavy-duty pavements bridges to ensure the best construction performance using the site resources available, to both minimise costs and prevent costly maintenance disruptions.

Geofabrics provide solutions that encompass all road types from temporary access tracks to site access road construction and port pavements. This also includes the construction of new airfield runways and taxiways.

- Utilisation of site won fill material

- Improved structural performance of roads, bridges, runways and heavy-duty pavements

- Serviceability of roads to maintain vehicle speeds, reduce maintenance, ensure safer operations and reduce truck depreciation

- Improved road surface performance of working and high traffic areas

- Low to high embankments

Airport and port pavements (near the sea) are often built on very soft ground which can raise considerable problems for design/geotechnical/airport engineers. Geofabrics offers technical solutions using different materials to accelerate construction on weak subgrades and can control differential settlement by creating a mechanically stabilised layer for runways and taxiways that cope with the intense loads from aircraft and heavy machine movements by reducing the aggregate required, extending the service or design life; and producing the potential for a significant cost, time and environmental benefits.

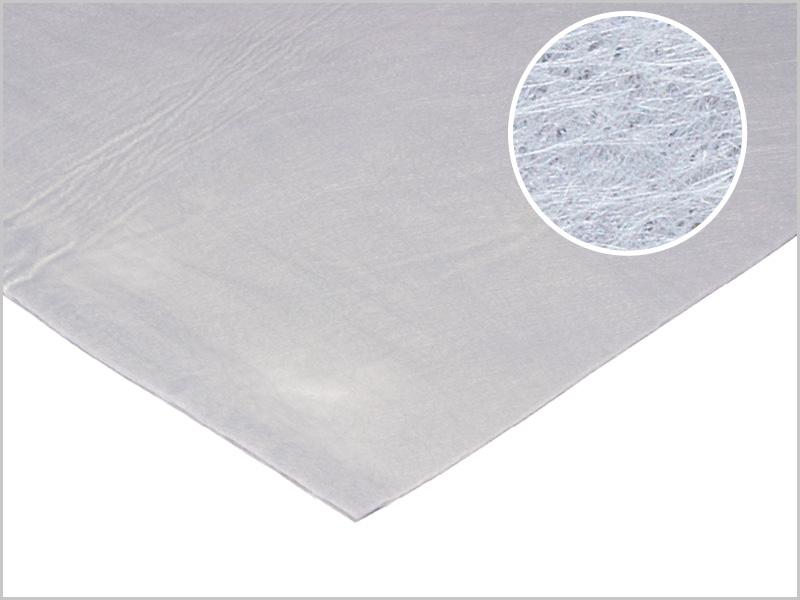

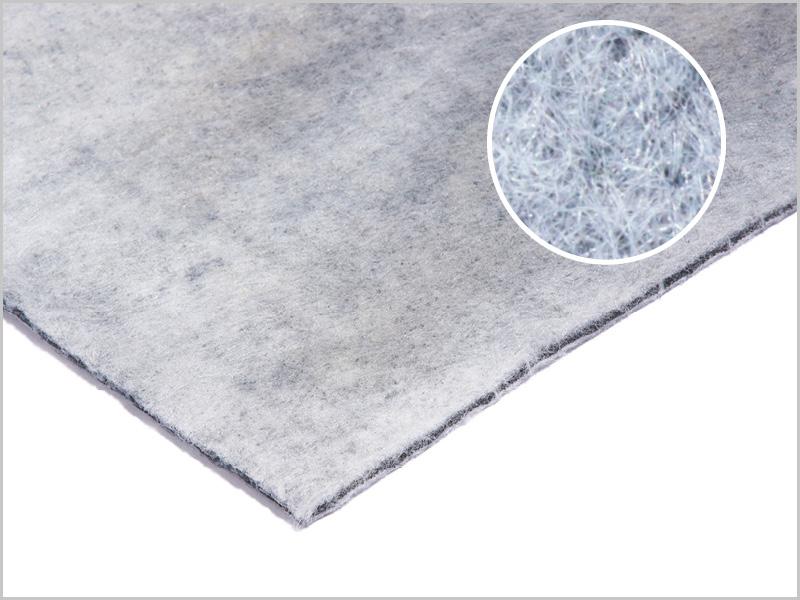

Geofabrics subgrade stabilisation solutions include Bidim Green non-woven geotextiles to provide separation and filtration between the subgrade and base layers.

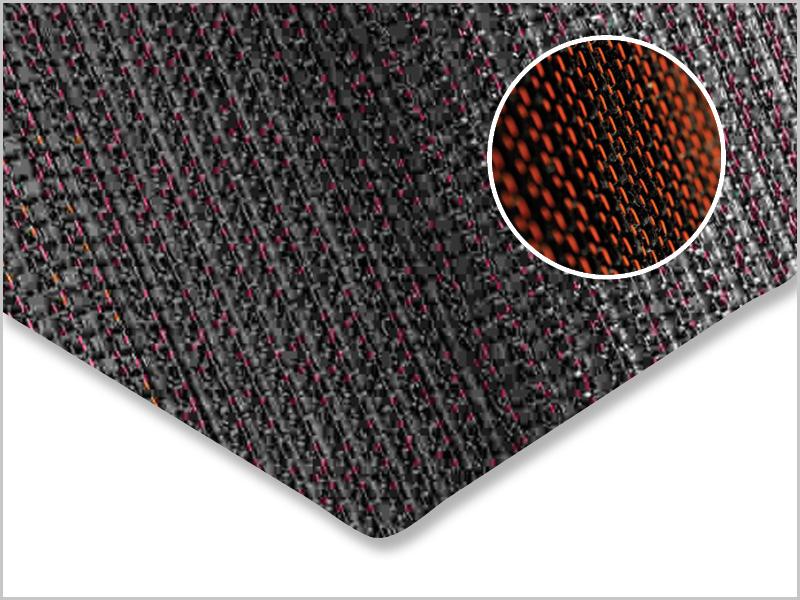

Asphalt Sealing & Reinforcement

Asphalt reinforcement is an important part of rehabilitation in road construction. Due to the constant passage of heavy military vehicles, higher strains are often imposed on asphalt pavements. These strains result in increased fatigue of the asphalt layers. As a result, the asphalt starts to crack, leading to premature failure and deterioration of the pavement due to water ingress.

Geofabrics offers a range of asphalt reinforcement product solutions that can be applied to roads, heavy-duty pavements, taxiways and runways which:

- Lower lifecycle costs of asphalt overlays by up to 20 – 30%

- Provide quick & easy installation

- Increase performance with thermal and chemical stability

Reinforced Slopes & Retaining Walls

Geofabrics offers a range of engineered slope, embankment and retaining wall solutions.

- Improved surface stability of mild slopes, watercourses and spillways

- Construction of large height retaining walls

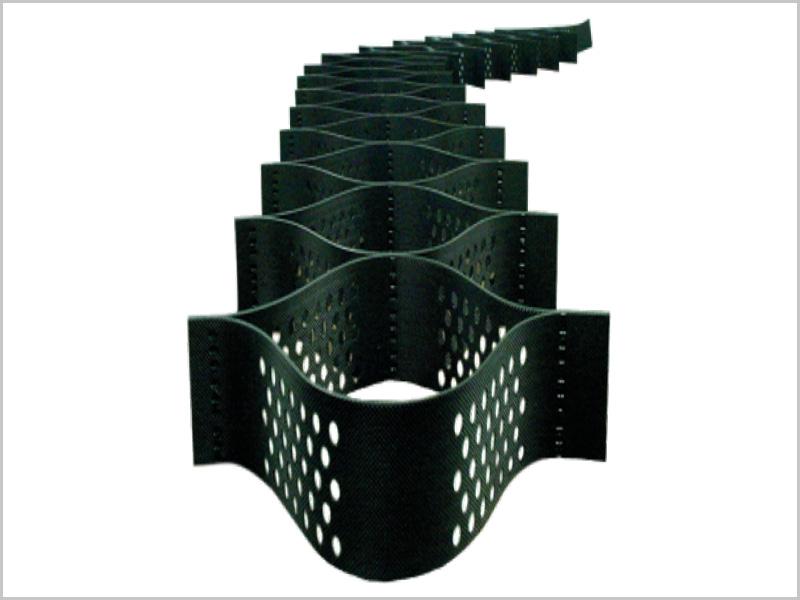

- Provide a protective or defence barrier for bases, personnel, vehicles and other critical infrastructure from any attacks with cellular containment walls

To support the design of retaining walls, slopes and embankments, we offer an advanced suite of software free to our clients. The Geofabrics team of engineering specialists are available to give technical advice in the use of the software as well as provide in-house or seminar training.

Erosion & Sediment Control

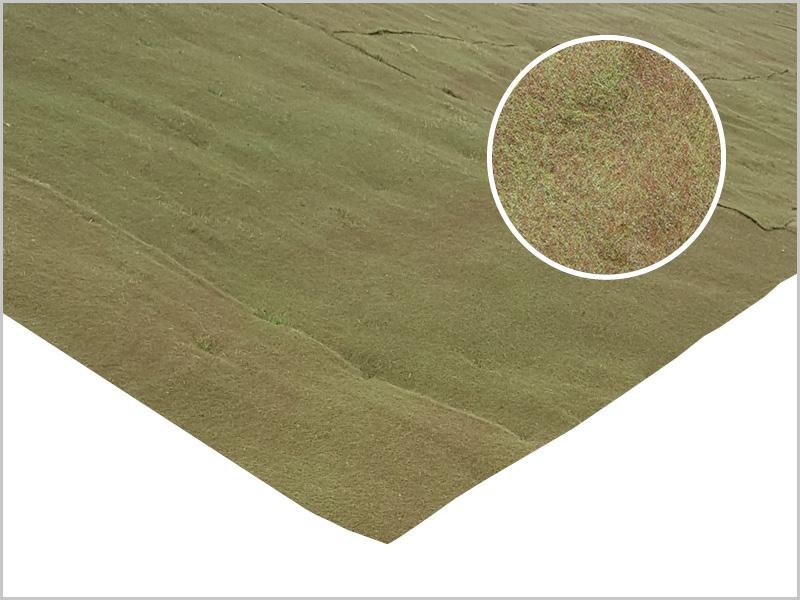

Enhancement of erosion performance of vegetated cover material on slopes can be achieved using a range of different geosynthetic solutions. This includes Grassroots, a synthetic erosion control matting designed to withstand higher-velocity water flows. Where there is insufficient soil on the slope to sustain vegetation, Geoweb can be installed, filled in with soil and planted.

Containment Lining & Capping

Aqueous film-forming foams (AFFF) containing PFAS were used prolifically in Australia from the 1970’s through to the early 2000’s at both civilian and military sites to extinguish flammable liquid fuel fires for training and emergency response purposes. They were highly effective due to the inclusion of two very specific long-chain fluorinated PFAS as active ingredients, namely perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS), with perfluorohexane sulfonate (PFHxS) also found as an impurity in the AFFF manufacturing process.

Sorbseal Hybrid Geosynthetic Clay Liner

Due to their persistence in humans, animals and the environment, the Department of Defence (DoD) began phasing out AFFF’s containing PFOA and PFOS in 2004, and initiated an extensive PFAS investigation and management process to identify, monitor and where necessary, remediate any of their sites around Australia which may have been impacted by these legacy chemicals. In some cases, such as open drain and source area excavations, impacted material may need to be removed from the site and disposed of at a licenced facility. This is where Sorbseal can help.

Sorbseal has a particular affinity for trapping PFOA and PFOS and can be used in conjunction with an overlying geomembrane to form a single or double composite liner, for effective containment and encapsulation of these materials. It works by providing very low permeability to percolating liquids through the use of a high purity, powdered sodium bentonite clay layer, combined with a powerful, high specific-surface area powdered activated carbon adsorbent. Sorbseal has been shown to be very effective in trapping a wide range of PFAS, including PFOS, PFOA and PFHxS, even within liquids containing potentially fouling co-contaminants, such as landfill leachate.

Coastal Protection & Remediation

Geofabrics geosynthetics offer reliable, cost effective and proven solutions for shoreline and marine protection.

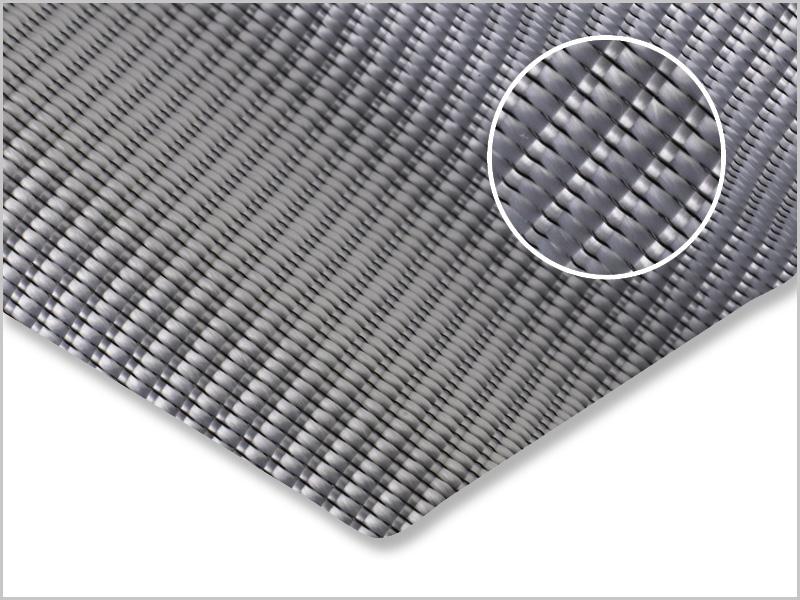

Once in position, geosynthetic solutions and systems can provide long term performance in protecting shorelines, rebuilding beaches, or reclaiming land. Geosynthetic materials are commonly used to reinforce the construction of sea walls, dykes and levees, jetties, groynes, revetments, breakwaters and bund walls for reclamation which are often constructed over weak materials such as mud, sludge and saturated silts or clays.

The use of Geofabrics geotextile solutions were critical in expanding the Brisbane Port which is located at the mouth of the Brisbane River by reclaiming and redeveloping an additional 230 hectares of land.

Flood Protection

Floods cannot be prevented but can be managed with Maccaferri FlexMac, a lightweight and flexible unit made of hexagonal double-twisted wire mesh, that is reinforced with steel rods and internally lined with a non-woven geotextile. The units are filled with available materials such as sand and gravel, to create a longitudinally safety barrier around critical infrastructure.

For flood mitigation and control, FlexMac is 40 times faster to construct than traditional sandbags; enabling quick response times and rapid deployment in emergency situations.