BUILDING ACCESS ROADS ON MT GELLIBRAND WINDFARM

PROJECT DESCRIPTION

The Victorian State Government is committed to increasing renewable energy generation and distribution in the state. To support this commitment, the government has undertaken a dual strategy of closing coal thermal power stations and approving the construction of a number of windfarms to close the gap on energy production. The construction of Mt Gellibrand Windfarm was approved in 2006 and the tender was awarded to Acciona Energía in 2008.

OUR SOLUTION

To develop the windfarm, 27km of internal unpaved access roads, 92,000m² of turbine hardstand areas and over 16,000m³ of structural concrete associated with the turbine foundations were required.

The site presented a number of challenges for the design team such as the need to create hardstands capable of withstanding heavy trafficking from construction vehicles, including a 600t tracked crane and 500t wheeled crane that were required for mobilising the turbine engines. Other considerations were the cost of high-quality fill materials and their distance from the site and the California Bearing Ratio (CBR) of <1.5.

To help develop a cost optimised solution for the project, the Acciona Energia team contacted Solmax, the leading provider of geosynthetics and industrial fabrics for preliminary evaluations on the access roads. According to the design checks that were conducted for access roads using Solmax® Mirafi RS380 Multifunctional Woven Geotextile, the performance met the acceptable limits, allowing a 600t tracked crane and 550t wheeled crane to safely traverse from one hardstand area to another. For the hardstand area to achieve a minimum safety factor of 1.3, 400mm thick pavement layers were suggested as it was difficult to eliminate the superficial deformation through load transfer plates of the cranes due to the characteristics of the available granular fill.

After verifying the hardstand design with different design guidelines such as Finite Element Analysis, Acciona Energía’s design team accepted the use of 400mm thick Mirafi RS580i to reinforce the economical fill pavement layer over subgrade UDS of 50kPa. The unique characteristics of Mirafi RS580i allowed the contractor to place locally available economical fill material without compromising the performance of the hardstand areas.

During construction, 150,000m² of Mirafi RS580i was incorporated into the hardstand areas with Geofabrics providing installation assistance to the contractor to ensure it was carried out according to the manufacturer’s recommendations.

For one tower, each blade weighed approximately 17.5t, with four towers weighing 220t in total. Over the complete installation process, more than 18,000t of turbine infrastructure will be moved into place over the Mirafi RSi reinforced hardstand areas and unpaved access roads.

PRODUCT USED

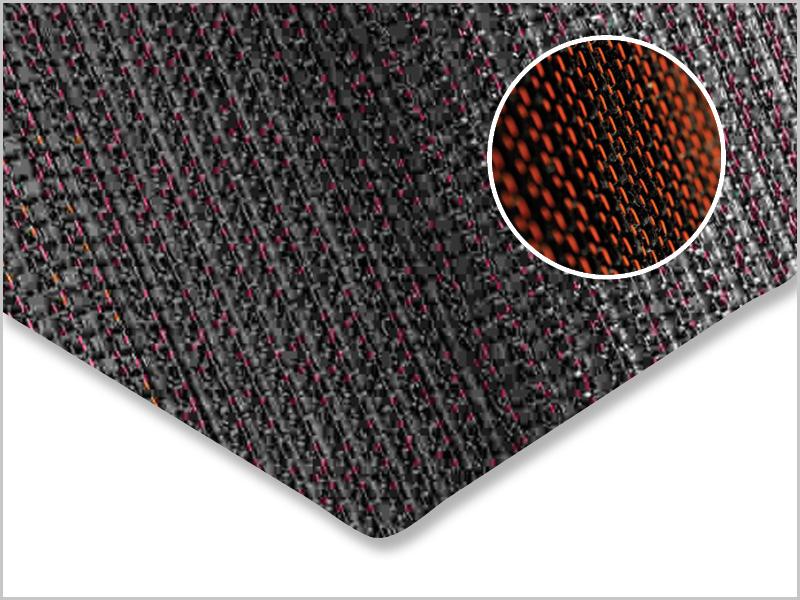

Solmax® Mirafi RSi Multifunctional Woven Geotextile

- Unique double layer construction made from high-tenacity polypropylene filament provides superior reinforcement strength and soil interaction, resulting in greater load distribution

- Robust structure that withstands the effects of rough dumping and filling with minimal damage

- Material cost savings of up to 33% by reducing the amount of base material required

- Easy installation by simply laying and aligning the system