Pavement Rehab and Reconstruction

The road pavement of a busy public bus turn-out had become damaged, uneven and unserviceable due to high levels of ground water and insufficient sub-surface drainage. The turn out was approximately 150 m long and was subject to very heavy and continuous loads.

The designer and a geotechnical engineer recommended excavating down 350 mm, improving subsoil drainage, cement treating 150 mm class 2 crushed rock, then 200 mm asphalt.

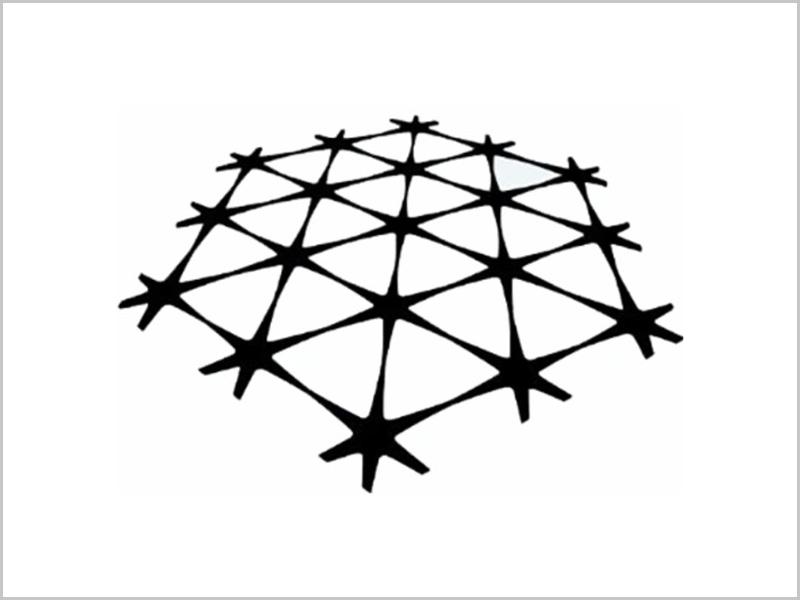

Cement treatment could not be done so the engineer advised to place a layer of Tensar TriAx Tx160 over the subgrade, 150 mm class 2 and asphalt - prior to engaging Geofabrics for technical advice.

Once Tensar TriAx Tx160 was laid and crushed rock was trucked in, the contractor contacted Geofabrics concerned about the performance of the Tensar TriAx Tx160 due to the “wave effect” of the TriAx being forced up through the 150 mm layer. They also advised that there was significant deformation in the crushed rock layer from trucks running over. At this point they were advised that if the subgrade was that soft then there should be a separation geotextile placed first and that the 150 mm may need to be increased within the soft areas.

Council then engaged Tensar whom forwarded the concerns back to Geofabrics. Geofabrics met with the council, contractor and engineer to inspect the site, it was noted and obvious that the subgrade appeared to have a far less CBR value than the 4-5% that the design was based on.

Geofabrics advised that in the soft areas, further excavation would be required (suggested additional 150 mm) a separation geotextile (bidim A24) be placed over the subgrade, crushed rock base be placed over the top, once compacted and level, lay the Tensar TriAx Tx160 and then add the 150 mm class 2 crushed rock and asphalt.

The engineer remained on site throughout the process to advise on areas needing further excavation and testing of compaction, proof roll was conducted and deformation was within specification.

The council needed a prompt solution after the initial design failed during installation, as the program of works had a permit for eight days shut of road lane and bus stops. An additional seven days was granted so they needed a solution that they could be assured would work. Geofabrics could assure that the proposed solution will give the results they needed and could be completed in the timeframe.

The geotechnical engineer and the council were both advised to engage Geofabrics at the early design stage in the future to prevent these failings happening again. The council was most appreciative of the technical support and time spent on site to resolve the issue which had the potential to cost them a considerable amount of time and money.

DOWNLOAD THE CASE STUDY

Pavement Rehab and Reconstruction