IMRPOVING THE FOUNDATION ON AXBRIDGE ROAD WITH TENSAR INTERAX

PROJECT DESCRIPTION

The project required the provision of a capping layer over weak ground, and the accommodation of construction traffic. It also had to provide a construction detail that would satisfy the requirements of the adopting authority, in this case Somerset County Council.

A capping layer was required to reduce the thickness of aggregate whilst achieving a surface modulus of 50MPa (5% CBR) which is equivalent to a foundation class 1 in CD225. Somerset County Council had concerns regarding possible utility work in the future that would compromise any geogrids positioned within the carriageway. One of their key requirements was to allow only a single layer of geogrid.

OUR SOLUTION

The original design for the Tensar mechanically stabilised layer (MSL) contained 2 layers of grid to accommodate the poor ground. A re-design was carried out using Tensar InterAx, which required a single layer of geogrid and offered a reduction in overall thickness of the capping layer.

PRODUCT USED

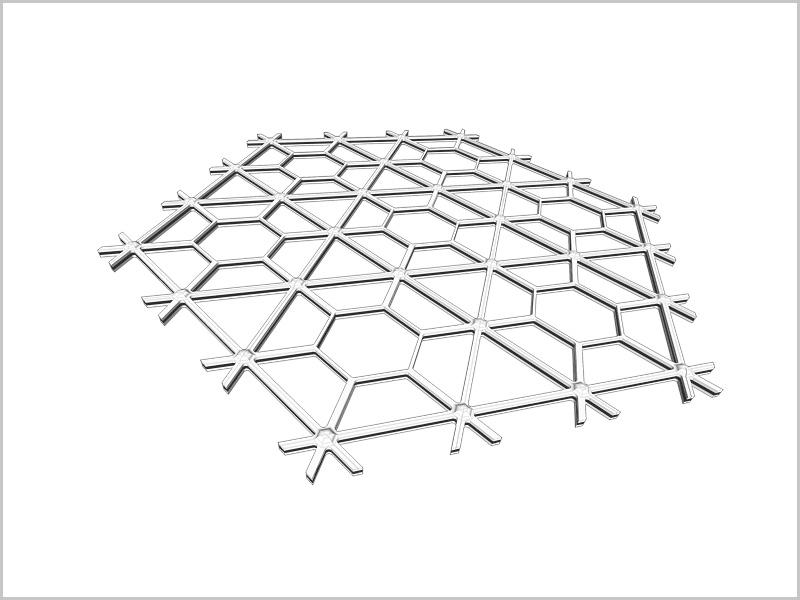

Tensar® InterAx® Geogrid

- Speeds up construction, saving up to 70% in aggregate section reduction

- Optimised geometry design for maximum confinement and compaction of granular fill, creating the most efficient mechanically stabilised layer (MSL)

- Improves compaction and restrict the movement of the particles over time, retaining the stiffness long term and further enhancing performance of the MSL

- Results in a more resilient solution that will withstand severe weather events, the increasing impact of climate change, and other challenging environmental conditions

- Improves interaction between the geogrid and aggregate for better performance

- Less aggregate is required to meet project requirements, which leads to savings on cost, time and carbon emissions

- Ideal for subgrade stabilisation, roads, heavy-duty pavements, and working platforms