DESIGNING A HEAVY-DUTY PAVEMENT FOR A CONTAINER YARD

PROJECT DESCRIPTION

The project involved the development of a new industrial subdivision in Cambridge, west of Hobart in Tasmania. Prior to construction, the area was predominantly flat and had a grassed surface with poor drainage. To accommodate its container handling and storage facility, the client, Castlerock Property, identified the need for a heavy-duty pavement. Due to the frequent operation of heavy-duty container lift trucks onsite with heavy axle loads of 280kN, a thick pavement solution was required.

OUR SOLUTION

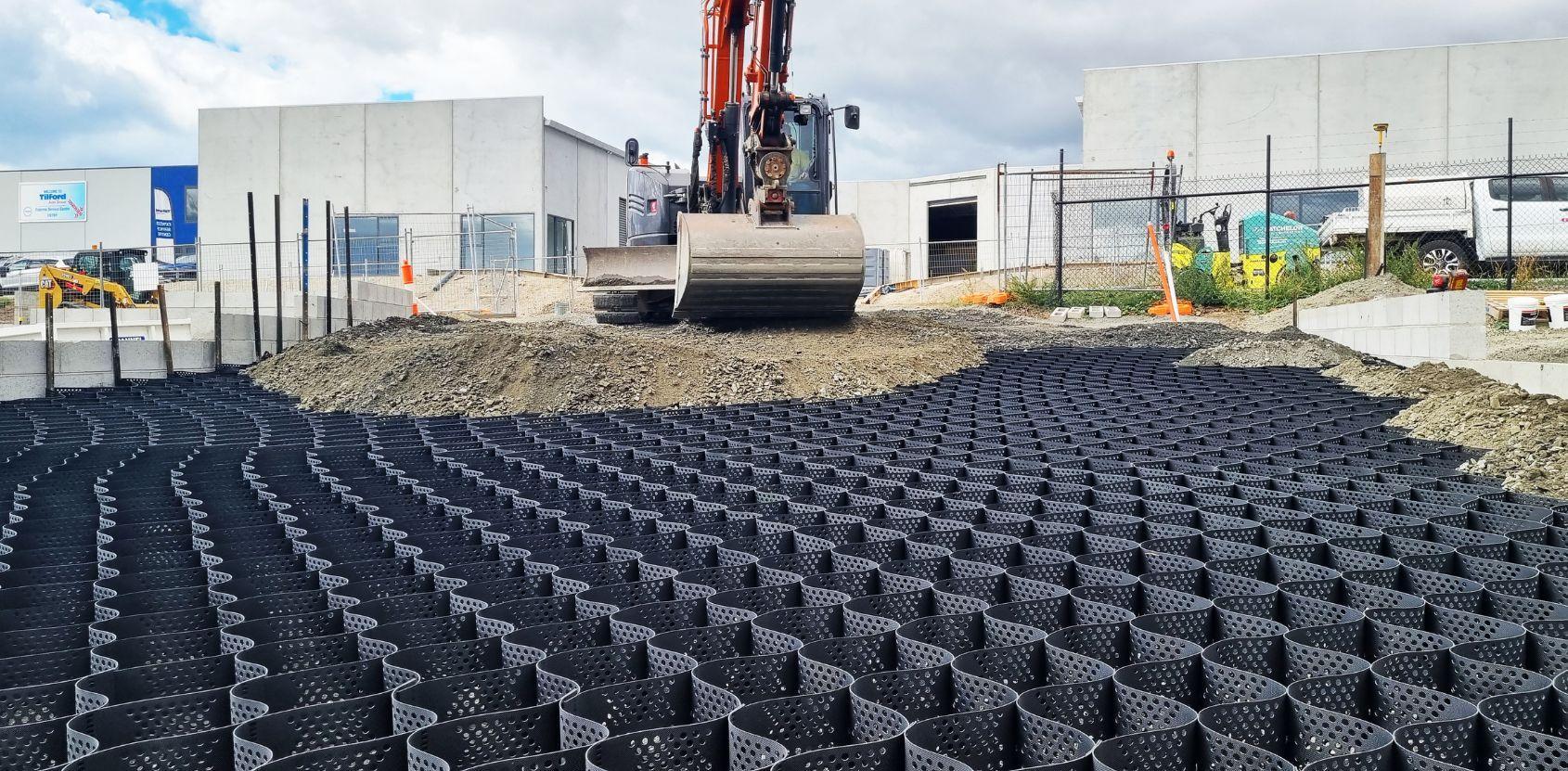

Geofabrics worked closely with the manufacturer, Presto Geosystems and local distributor, Geotas to develop a solution aimed at optimising and stabilising the pavement. An evaluation of the pavement was undertaken using geosynthetics, which demonstrated a significantly thinner pavement than the initially proposed design. Geofabrics provided technical assistance to the client’s geotechnical engineer, helping them certify the design incorporating Presto Geoweb cellular confinement geocell system and Solmax Mirafi RSi multifunctional woven geotextile.

The subgrade preparation involved the installation of Mirafi RS380i with a 100mm base layer made from crushed rock. This base layer integrated the placement of Geoweb GW30V6, which was infilled with additional crushed rock. Following this, the levelling layer and wearing course were built with the pavement having a granular wearing course for most of the site. Throughout the pavement construction process, Geofabrics provided onsite support for the installation of both Geoweb and Mirafi RS380i, which was carried out by the contractor, Batchelor Construction Group.

By installing Geoweb and Mirafi RSi, the client was able to adopt a pavement that was around 350mm thick and 50% thinner than the initially proposed pavement design. This resulted in significant cost savings across the 2,000m² project area. A site visit was conducted nearly a year after construction, with observations showing that the Geoweb and RS380i system continues to perform well.

PRODUCT USED

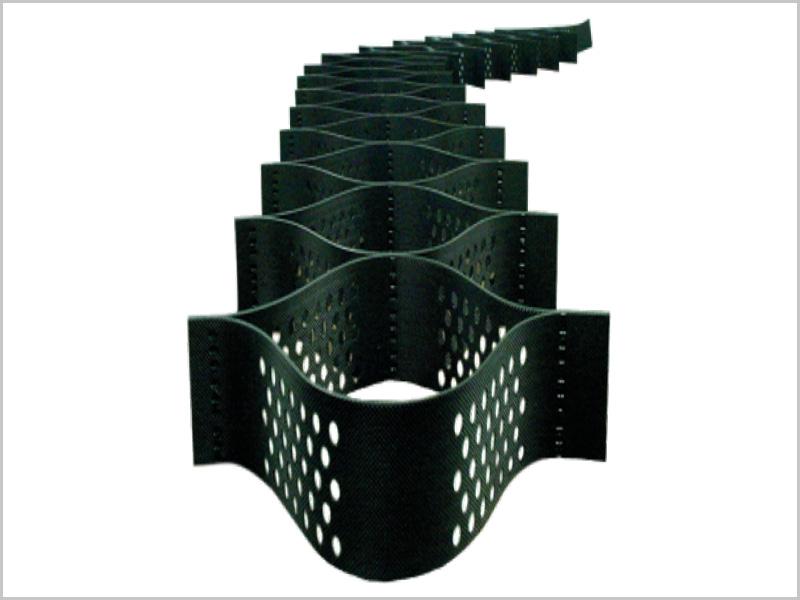

Presto Geoweb® Cellular Confinement Geocell

- Robust UV resistant, three-dimensional structure that confines and compact soil to prevent erosion and improves the structural performance of the soil or aggregate infill

- Quick installation through the use of patented ATRA clip connection system or high strength tendons, saving on installation costs

- Eco-friendly soil stabilisation solution that blends into the natural environment

- Reduces the thickness of structural support elements by 50% or more

- With different types of infill, perforations allow infill to interlock with the cell walls, increasing frictional resistance, creating a better armoured slope

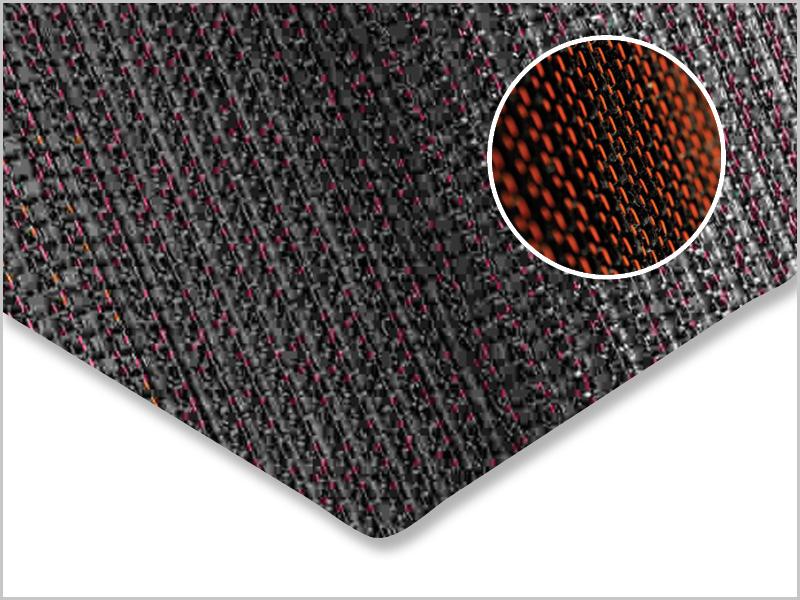

Solmax Mirafi® RSi Multifunctional Woven Geotextile

- Superior separation and filtration capability with effective prevention of aggregate mixing and loss of sub-base material into soft subgrade

- Material cost savings of up to 33% by reducing the amount of base material required

- Double layer construction made from hightenacity polypropylene filament, provides superior reinforcement strength and soil interaction capabilities by allowing high water flow and soil retention within a roadway system

- High permeability with efficient release of pore water pressure which makes it suitable for installation over soft wet soils