CONSTRUCTING A GABION RETAINING WALL AT PORT MORESBY

PROJECT DESCRIPTION

The project was to construct a multi-million-dollar residence that overlooks Idlers Bay on top of a steep sloping block in Port Moresby, Papua New Guinea (PNG). To provide this multi-levelled home with a solid foundation for build, an 8-metre-high gabion retaining wall had to be constructed. The client was looking for an economical retaining wall solution that will support the house and have a natural, aesthetic finish to blend in with its surrounding.

OUR SOLUTION

Geofabrics in consultation with the engineer, Kramer Ausenco assisted with the conceptual design by providing technical support on product recommendations and analysis of the gabion earth retaining wall. Markham Culverts, our distributor in PNG were on site when required to ensure that the design was followed accordingly by the installer.

Upon inspection, the site was deemed unsuitable for build due to its irregular foundation. The site had to be excavated 7 metres deep to provide a level platform for the construction of the gabion baskets. A total of 155 gabions were installed and filled with rocks sourced from the site to construct an 8m high by 52m long retaining wall which was further reinforced using TenCate Miragrid GX Geogrid.

To achieve the client request for a retaining wall with a natural finish, 2m x 60m rolls of Grassroots Synthetic Erosion Control Mats were installed between each layer of gabion. Grassroots will help to encourage the growth of vines around the gabion baskets, resulting in a green vegetated wall.

PRODUCTS USED

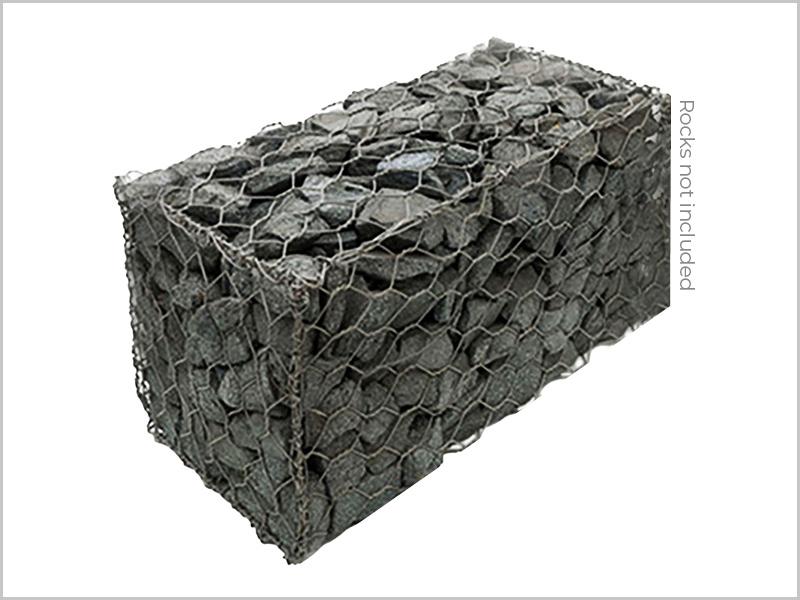

MACCAFERRI® GABION BASKETS

- Double-twisted wire mesh container uniformly partitioned, interconnected and filled with rock to create flexible, permeable structures

- Built to retain earth and combat soil erosion

- Delivered to site flat-packed, where they can be assembled, placed into a stepped, vertical or battered position and filled with quarried rock or stone ranging between100mm to 200mm

- Made from high-quality steel wire with the option to apply a protective polymeric coating, PoliMac® that is used to withstand harsh conditions, and where a longer design life is required