Kent Storage Detention Tank

A site used by Kent Storage for container storage required an underground detention tank due to limited above ground space. Due to the extreme loads associated with containers and frequent movements of heavily loaded forklifts, a reinforced subsurface concrete tank was the initial choice. However, other options were considered due to the high cost associated with supply and installation of the concrete tank.

Davison Earthmovers tendered the project with an alternate system in ecoAID Stormwater Chambers. EcoAID was approximately half the cost to install than the proposed concrete tank and therefore was preferred. There were some questions around ecoAID’s load capacity and structural performance when installed under containers and within pavements that were likely to cater to 25 T axles loads. Any concerns were alleviated as Geofabrics were able to produce an independent Finite Element Analysis (FEA) report which was able to illustrate the EcoAID system could withstand the proposed loads.

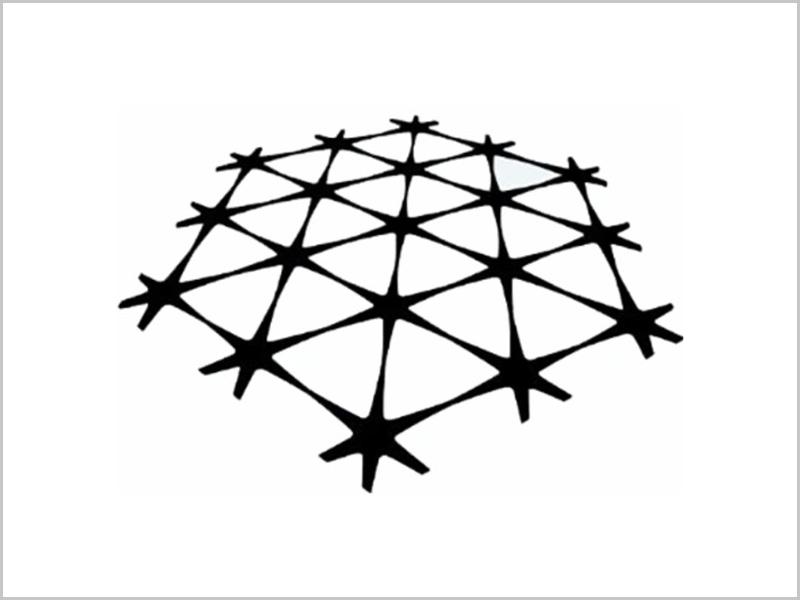

The FEA report detailed that if the pavement was sealed with reinforced concrete then the 600 mm cover was acceptable, however the pavement would need to be stabilised with a layer of Tensar TX170 geogrid. If the cover was increased to 800 mm then no additional stabilisation was required.

It was noted that if the surface comprised a flexible asphalt seal then more pavement improvements would be required. In this case the pavement was concrete, however in order to limit risk, the extra cover of 800 mm was implemented, and two layers of geogrid was placed at 300 mm centres within the pavement.

Geofabrics were able to assist the designers and the contractor with sizing up the system to suit the available footprint and provide adequate information to prove the system could withstand the given loads. Geofabrics were also able to assist on site to ensure the arches were placed in accordance with the manufacturers specification.

Davison Earthmovers were able to install the system extremely quickly while the impermeable 1.5 mm HDPE liner was installed and welded in situ by Polydam.

The site is still under construction, but the system is already carrying heavy construction loads with minimal deflections observed on the surface.

The result was an economical alternative to a concrete tank that could withstand the proposed loads for the 50 year design life of the system.

DOWNLOAD THE CASE STUDY