GROYNE RECONSTRUCTION IN PORT OF DARLOWO, POLAND

PROJECT DESCRIPTION

The existing shore protection system, located east of the Port of Darłowo, Poland, comprises 53 wooden groynes, consisting of 39 L-type groynes and 14 T-type groynes, each measuring approximately 110m in length.

The groynes have sustained significant damage and require urgent repairs. Disturbances to the water currents in the coastal zone were caused by this damage, leading to a reduction in sedimentation capacity. Due to the rapid erosion of the seashore in the area, further unfavourable changes in the coastal zone and position of the coastline may occur.

OUR SOLUTION

This project involved the reconstruction of 53 existing wooden groynes. As part of the process, piles that have been deflected or damaged were removed and replaced with longer piles with new clamping installed.

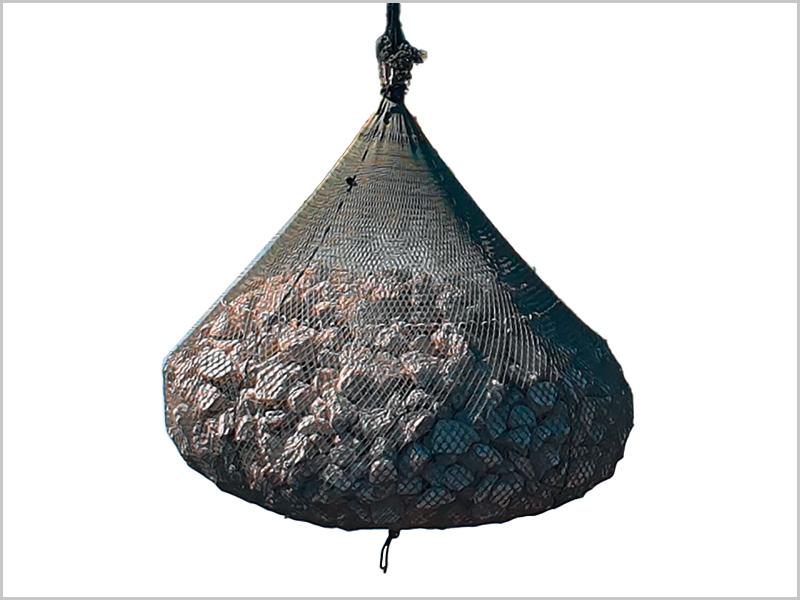

Following the groyne reconstruction, the bottom was strengthened using anti-erosion nets filled with stones (2T AquaRockBags) to enhance stability. By utilising AquaRockBags, the client saved on labour costs with its quick filling and installation process. The bags were filled in the warehouse yard and transported to the site, ready to be deployed.

PRODUCT USED

AquaRockBag

- The design of the bag facilitates the establishment of plant life on and around the bags, creating a natural habitat for aquatic ecosystems over a short period of time

- Offers minimal environmental impact during installation and can help avoid the need for extensive excavation or disruptive construction processes. This preserves the natural habitat and reduces the risk of secondary environmental damage

- Lower projects costs with a flexible net structure that adapts well to uneven surfaces, eliminating the need for ground preparation works with heavy machinery

- Adaptable to various site conditions and can be reused in different projects, the modular nature allows for easy reconfiguration and relocation • Net is fully recyclable and offers excellent anti-abrasion properties and high UV resistance

- The net can be filled on-site using a portable filling frame and machinery, which makes installation quick and easy. Only basic on-site staff training is required