BUILD STRONG PILING PLATFORMS WITH TENSAR TRIAX GEOGRIDS

PROJECT DESCRIPTION

The Baypark to Bayfair upgrade project improves safety by separating local traffic from the state highway and rail corridor, providing safer walking and cycling connections, and completing the State Highway to Eastern Corridor for the Bay of Plenty.

Geofabrics was already supplying geosynthetic products to this development when CPB Contractors reached out to our team with a new request, requiring assistance with the modelling and construction of a cost-effective and strong piling platform. This project design is critical as the piles are built as the foundation for two flyovers for a bridge overpass, at one of the busiest parts of the road network.

OUR SOLUTION

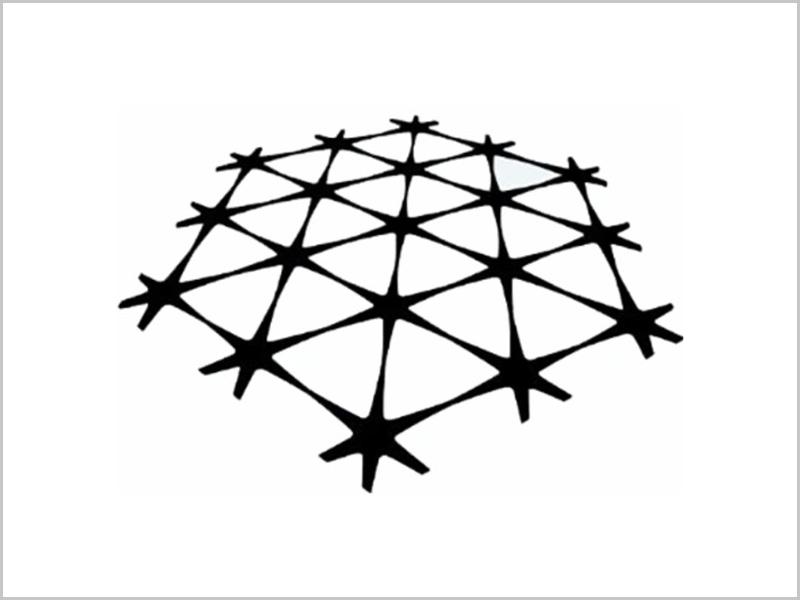

Geofabrics worked together with the Tensar technical team to prepare a preliminary evaluation for the piling platform. Tensar TriAx geogrids provide a stabilisation function where the aggregate particles within the granular layer interlock with the geogrid and subsequent particle confinement inhibits deformation. The structure is referred to as a Tensar Mechanically Stabilised Layer (MSL).

The original design concept incorporated a 40kN biaxal geogrid to be used in the platform. The Geofabrics’ application of Tensar TriAx Tx160 geogrid and the Tensar MSL resulted in a reduction of an additional 100mm thick pavement layer, saving $10,000 in aggregate costs, despite it being a small (1,000m²) area.

PRODUCT USED

Tensar® TriAx® Triaxial Geogrid

- Creates a Tensar Mechanically Stabilised Layer (MSL) by stabilising granular layers to perform as a composite with interlocking mechanisms, ensuring optimum performance and resulting in cost savings

- Increases the bearing capacity of working platforms for heavy-duty plant, cranes and piling rigs with geogrid load spreading capability

- Creates a flexurally stiff platform and smooths out the variable quality of support from a foundation soil

- Extends the service life of roads, significantly reducing maintenance budgets